Specifications:

| Materials | Hot-pressed ZnS | Diameter Range | ~ 280mm |

| Thickness Tolerance | +/-0.2mm (Optional:+/-0.1mm and +/-0.05mm) | Surface Quality | 60/40 S/D |

| Fringes (N) | customized | Irregularity (delta N) | customized |

| Chamfer | 0.1~0.3mmx45degree | Coating | AR coating |

Physical and Optical Properties:

| Transmission Range | 7.5 to 12μm | Knoop Hardness | 210 |

| Melting Point | 1830°C | Youngs Modulus | 80GPa |

| Bending Strength | >100MPa | Density | 4.08g/cm3 |

| Thermal Expansion | <9x10-6K-1(~600℃) | Refractive Index | 2.2004 |

| Transmittance | >70%(8-12μm) | Poisson Ratio | 0.25-0.36 |

| Specific Heat | 0.468J/(g*K) |

Thermal Conductivity |

19W/(m*K) |

CVD (Chemical Vapor Deposition) Zinc Sulfide or CVD ZnS is substituting and dominating the position occupied by Hot-pressed Zinc Sulfide the previous time. The CVD process involves the deposition of thin films or coatings onto a substrate through the chemical reaction of gaseous precursors. In the case of zinc sulfide domes, the CVD method allows for the controlled growth of ZnS films on a prepared substrate, resulting in a uniform and reproducible product. The use of CVD ensures precise control over the material's composition, thickness, and overall quality. CVD zinc sulfide excels or exhibits identical characteristics to hot-pressed zinc sulfide in terms of optical properties, mechanical properties, and thermal properties. The most distinguished advantage of CVD ZnS is its excellent optical transmittance, in particular, in the 10.5~12μm wavelength range, the transmission rate of hot-pressed zinc sulfide drops to a drastic extent, whilst CVD ZnS maintains a decent transmission rate. After coating, this difference in transmittance will be further amplified. This trait has a significant impact on the response of infrared uncooled systems. CVD ZnS, with a transmission spectrum of 8-12μm and twice the fracture strength of ZnSe and exceptional hardness, has found extensive use in uses in LWIR applications that demand mechanical resilience in hostile environments. Multispectral Zinc Sulfide, also called Cleartran, is a modified version of CVD ZnS that undergoes a further post-deposition hot isostatic procedure to expand the transmission range into 0.4-12μm. In comparison, besides the difference in transparent range, CVD ZnS is harder, although both of them are far more rugged than ZnSe.

North Optics is a professional manufacturer of CVD ZnS Domes and Multispectral ZnS Domes. Our CVD and Multispectral ZnS domes find widespread utilities in applications like Infrared imaging, missile guidance, scientific instruments, etc. Our ZnS domes boast outstanding optical transmission and minimal absorption/low scatters in the IR band, mechanical strength, and durability which is crucial in harsh environments, such as aerospace and defense. The controllable nature of the CVD process ensures the uniform deposition of zinc sulfide, resulting in homogeneous optical and mechanical properties across the entire dome.

Application Notes:

Part 1. Comparison between the physical properties of CVD Zinc Sulfide and Hot-pressed Zinc Sulfide. The chart demonstrates that CVD ZnS has much better mechanical robustness, thermo-mechanical steadiness, and optical transmission rate.

| Material | CVD Zinc Sulfide | Hot-pressed Zinc Sulfide |

| Density (g/cm^2) | 4.08 | 4.09 |

| Melting Point (°C) | 1830 | 1830 |

| Youngs Modulus (GPa) | 80 | 74.5 |

| Poisson Ratio | 0.25-0.36 | 0.29 |

| Specific Heat (J/g*k) | 0.468 | / |

| Thermal Conductivity (W/m*K) | 19 | 17.2 |

| Thermal Expansion Coefficients | <9x10^-6/K(~600°C) | 6.x10^-6/K to 7.9x10^-6/K(~600°C) |

| Transmission Rate | >70%(8-12μm) | >66%(7.5-10.5μm) |

| Refractive Index | 2.2004 | 2.1986 |

| Bending Strength | >100 | >90 |

| Knoop Hardness | 210 | 210 |

Part 2. Comparison between the transmission curves of CVD Zinc Sulfide and Hot-pressed Zinc Sulfide

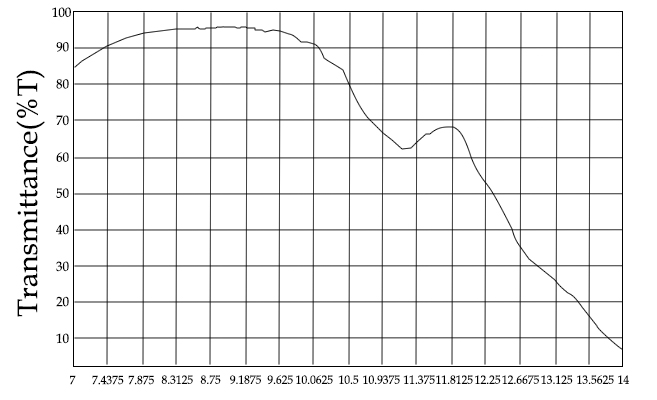

a). The requirements for hot-pressed ZnS dome are: transmittance in the 7.5~10.5μm band ≥85%, and transmittance in the 10.5~12μm band ≥70%. The measured curve of hot-pressed zinc sulfide after coating is shown in the figure below:

Figure 1. Transmission Curve of Hot-pressed Zinc Sulfide

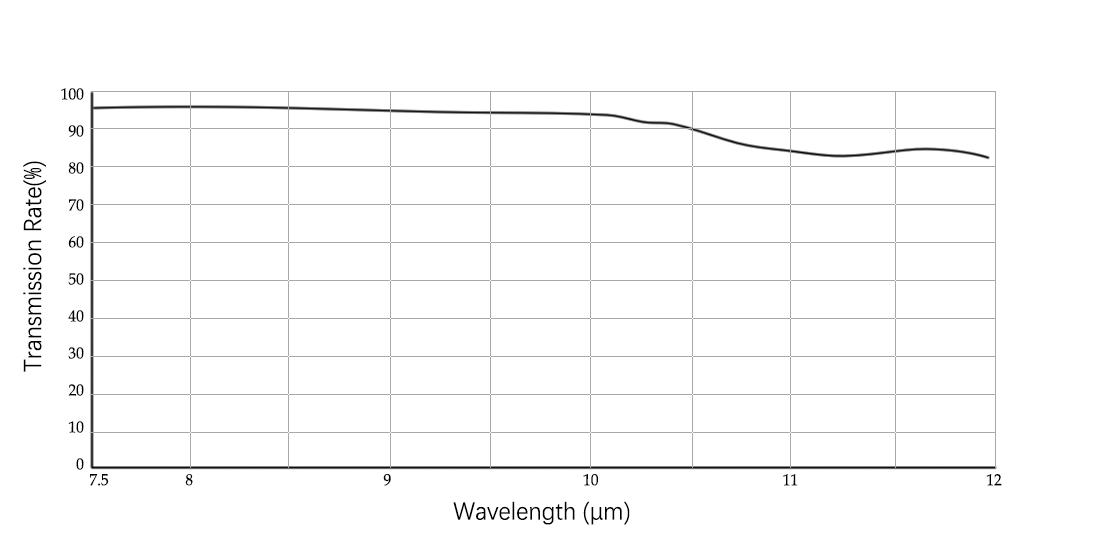

b). The measured curve of the CVD zinc sulfide dome after coating is shown in the figure below, it is evident that the transmission rate has been enhanced to a significant extent, which is beneficial to both the MRTD and NETD of the system:

Figure 2. Transmission Curve of CVD Zinc Sulfide

Curves:

The measured transmission curve of the CVD zinc sulfide dome after coating is shown in the figure below: